Register for Lindsay Scypta's Workshop from Home webinar: "Custom Decorating Tools!"

July 16, 2025, 11am–1pm EDT, US$44 Learn more about this webinar here.

Featured

-

How to Make a Lovely Scalloped Foot From an Added Coil

-

How to Fix Cracks in Pottery

-

How to Make a Better Homemade Sink Trap for Your Pottery Studio

-

How to Throw a Wide, Shallow Bowl

-

How to Replace Electric Kiln Elements

-

The Particulars of Clay Body Plasticity

-

Great Tips for Designing and Laser Cutting Tools

-

Drawn to Surface: How to Make and Use Underglaze Pencils, Crayons, Pens, and Trailers

Wheel Throwing Techniques

-

How to Throw a Wide, Shallow Bowl

How to Throw a Wide, Shallow BowlJuly 9, 2025

-

-

Hand Building Techniques

-

How to Make a Lovely Scalloped Foot From an Added Coil

How to Make a Lovely Scalloped Foot From an Added CoilJuly 11, 2025

-

8 Expert Tips for Making Perfect Plates

8 Expert Tips for Making Perfect PlatesJune 30, 2025

-

Ceramic Decorating Techniques

-

-

Connecting the Dots: Slip Dotting and Feathering

Connecting the Dots: Slip Dotting and FeatheringJuly 2, 2025

-

Browse Topics

Ceramic Art and Artists

Ceramic Glaze Recipes

Ceramic Supplies

Clay Tools and Equipment

Firing Techniques

Pottery Making Techniques

Best Sellers

-

From One to Many with Amy Sanders

Retail Price $26.98

ICAN Member Price $21.58

From One to Many with Amy Sanders

Retail Price $26.98

ICAN Member Price $21.58

-

The Anatomy of a Good Pot

Retail Price $36.98

ICAN Member Price $29.58

The Anatomy of a Good Pot

Retail Price $36.98

ICAN Member Price $29.58

-

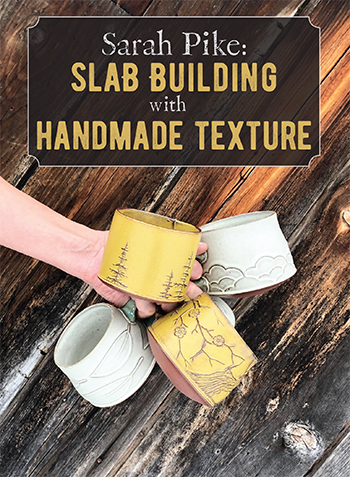

Slab Building with Handmade Texture with Sarah Pike

Retail Price $31.98

ICAN Member Price $25.58

Slab Building with Handmade Texture with Sarah Pike

Retail Price $31.98

ICAN Member Price $25.58

-

Precision Throwing & Intricate Carving with Adam Field

Retail Price $19.98

ICAN Member Price $15.98

Precision Throwing & Intricate Carving with Adam Field

Retail Price $19.98

ICAN Member Price $15.98

-

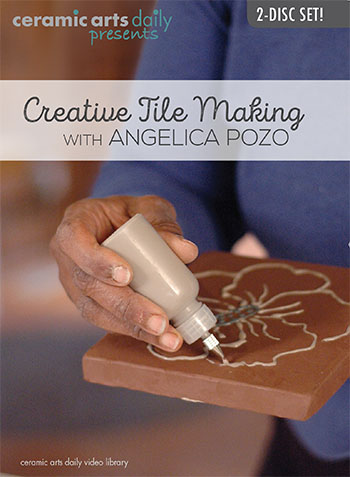

Creative Tile Making with Angelica Pozo

Retail Price $19.98

ICAN Member Price $15.98

Creative Tile Making with Angelica Pozo

Retail Price $19.98

ICAN Member Price $15.98

-

Special Effect Glazes

Retail Price $36.98

ICAN Member Price $29.58

Special Effect Glazes

Retail Price $36.98

ICAN Member Price $29.58

-

Working with Porcelain

Retail Price $41.98

ICAN Member Price $33.58

Working with Porcelain

Retail Price $41.98

ICAN Member Price $33.58

-

Science For Potters

Retail Price $36.98

ICAN Member Price $29.58

Science For Potters

Retail Price $36.98

ICAN Member Price $29.58