I have been working with a new chrome-tin pink glaze for the past year or so. It was the result of some color blends I had done. While I wasn't looking for a pink glaze necessarily, this one has become one of my favorites.

So I thought I would share some research that Ryan Coppage, PhD, Julie Krichev, and Craig Caudill have done on chrome-tin pinks and purples. By experimenting with chromium oxide, tin oxide, and cobalt carbonate, they’ve uncovered a lovely palette of soft pastels and vibrant hues that also happen to be affordable. And who doesn't love that? –Jennifer Poellot Harnetty, editor

If you’ve done any degree of searching for recipes, there are significant limitations to pink glazes and even pigments/stains. A quick search online or in any pottery supply store shows a diverse array of all the glazes in shades of greens and blues that one could hope for, but few pinks. But, apart from Mason stains (and even then, the shades are limited), the variety and availability of pink glazes are disappointing at best.

The most reliable standard for pink glazes, erbium oxide (Er2O3), is a rare earth metal that produces a translucent light pink in 8–10% amounts (1). While erbium produces this highly sought-after light pink, it is relatively unaffordable for most to casually mix up a bucket. One pound of erbium oxide goes for about $120, while a pound of chromium oxide is about $28 (and you use 2000-fold less by weight!). In addition, chromium oxide produces a light pink, similar to that of erbium oxide, at around 0.005%, much less than the already more expensive erbium. The addition of 10% erbium oxide in 10,000 grams of glaze (about 2⁄3 of a standard 5-gallon bucket) would be around $264. In comparison, the addition of 0.005% chromium oxide and 5% tin oxide to 10,000 grams of glaze would cost around $141 (the large majority of this due to the addition of tin oxide, as the chromium oxide alone would only cost three cents).

Other pink glazes tend to be difficult to use and are limited to specific conditions, such as coating thickness and firing temperatures.

In attempts to create a new pink standard, one that is highly more affordable and easier to use, we started with the raspberry chromium oxide glaze. This glaze has a high cassiterite concentration (tin oxide (SnO2)). Cassiterite forms a crystal structure which helps prevent light from traveling through the glaze—creating an opacifying effect. In order to produce pink (rather than a deep red), we started scaling back the amount of chromium oxide introduced to the 5% SnO2 glaze, as that was when a clear, unmuddied red was first observed. If there is a lower concentration of chromium oxide to occupy the tin crystal lattice, and the same overall opacity, a lower saturation and more pastel red should be found. After eighteen chromium down-ramps, we found that while most red chromium glazes use around 0.2% chromium oxide, even 0.005% chromium oxide was enough to produce a soft pink, while anything at or above 0.025% seems to transition back toward the deeper raspberry red colors (2).

While these chromium amounts yield the desired shades of pink, they also produce speckles—possibly due to concentrated color centers. These color centers likely arise from defects in the structure of the tin-chromium lattice. While the speckling may be an effect that is desirable to some, it can be reduced by using a ball mill to evenly distribute the chromium oxide.1

With pinks set, it was pondered if purples could also be developed the same way. Traditionally, purples (similarly to pinks) are hard. The most common purple is neodymium oxide, making a dichroic lavender. It has about the same cost as erbium: $120/pound. And the pigment loading for neodymium is about the same, ringing in at 8% or so. That’s more than $200 for a bucket in just pigment alone.

Cobalt is a relatively strong pigment (but not so sensitive as chromium in tin, as shown earlier), so it was added in 0.05% increments and then doubled in the last row at 0.40%. This made for quite a colorful set of glazes that, to our knowledge, hasn’t been developed or shared to this date (3).

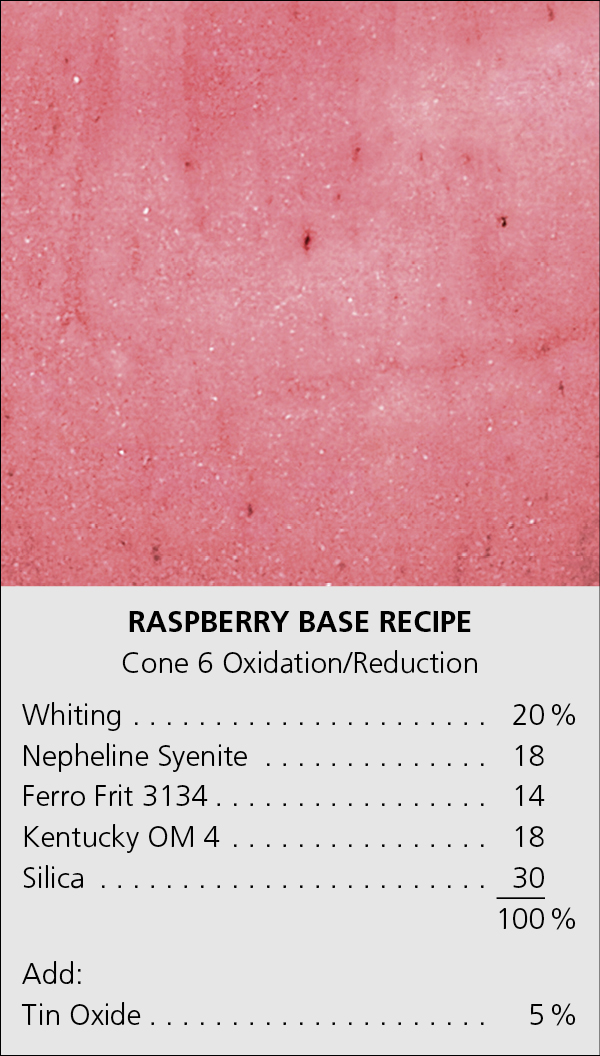

Raspberry Base Recipe

This is the base recipe for tin and chrome glazes to produce pinks and purples. Ferro frit 3134 provides a high calcium content that is essential in achieving the desired pink color.2 Calcium (in Ferro frit 3134) helps achieve opacity in the glaze at higher temperatures.3 It should also be noted that zinc should be avoided in this glaze recipe as it results in varying shades of brown. This could be because zinc could compete with chromium for open sites in the cassiterite crystal matrix (which chromium otherwise occupies and results in vibrant pinks and raspberries).

To obtain Julia’s Pink, as seen in the first mug for this article, add 0.010% Cr2O3 to the Raspberry Base Recipe. Be sure to pay attention to decimal places. It will be a very small amount of chromium!

While the exact mechanism for chromium-tin pink and raspberry glazes is not currently fully agreed upon, several different phenomena are taking place, including nanoparticle formation, chromium substitution in cassiterite matrix, and likely competition between Cr and Sn for that matrix position. It is interesting that nanomaterial quantities of chromium oxide are required for vibrant pinks and reds—much akin to metal loading content for nanoparticle gold and silver glazes as well.

Hopefully, this grid of pinks to purples helps those in need and inspires others to look at commonly used recipes and ask themselves how they work—and then start changing additives in the recipes. This range of pinks and purples has been sitting under potters’ noses for a decade now, just waiting for someone to ask how it works.

the authors Julia Krichev is a swimmer at the University of Richmond. She is currently studying biochemistry and visual arts at the University of Richmond.

Craig Caudill is currently pursuing a master’s of public health in epidemiology at the University of Michigan. He is a recent graduate from the University of Richmond, earning a BA with honors in leadership studies.

Ryan Coppage is currently chemistry teaching faculty at the University of Richmond. He fiddles with various glaze projects and makes a reasonable number of pots. To see more, visit www.ryancoppage.com.

Search the Daily

Published Oct 6, 2025

I have been working with a new chrome-tin pink glaze for the past year or so. It was the result of some color blends I had done. While I wasn't looking for a pink glaze necessarily, this one has become one of my favorites.

So I thought I would share some research that Ryan Coppage, PhD, Julie Krichev, and Craig Caudill have done on chrome-tin pinks and purples. By experimenting with chromium oxide, tin oxide, and cobalt carbonate, they’ve uncovered a lovely palette of soft pastels and vibrant hues that also happen to be affordable. And who doesn't love that? –Jennifer Poellot Harnetty, editor

PS. Go deeper into this topic in the full article in the October 2025 issue of Ceramics Monthly! Not a subscriber? Subscribe today!

Pink!

If you’ve done any degree of searching for recipes, there are significant limitations to pink glazes and even pigments/stains. A quick search online or in any pottery supply store shows a diverse array of all the glazes in shades of greens and blues that one could hope for, but few pinks. But, apart from Mason stains (and even then, the shades are limited), the variety and availability of pink glazes are disappointing at best.

The most reliable standard for pink glazes, erbium oxide (Er2O3), is a rare earth metal that produces a translucent light pink in 8–10% amounts (1). While erbium produces this highly sought-after light pink, it is relatively unaffordable for most to casually mix up a bucket. One pound of erbium oxide goes for about $120, while a pound of chromium oxide is about $28 (and you use 2000-fold less by weight!). In addition, chromium oxide produces a light pink, similar to that of erbium oxide, at around 0.005%, much less than the already more expensive erbium. The addition of 10% erbium oxide in 10,000 grams of glaze (about 2⁄3 of a standard 5-gallon bucket) would be around $264. In comparison, the addition of 0.005% chromium oxide and 5% tin oxide to 10,000 grams of glaze would cost around $141 (the large majority of this due to the addition of tin oxide, as the chromium oxide alone would only cost three cents).

Other pink glazes tend to be difficult to use and are limited to specific conditions, such as coating thickness and firing temperatures.

In attempts to create a new pink standard, one that is highly more affordable and easier to use, we started with the raspberry chromium oxide glaze. This glaze has a high cassiterite concentration (tin oxide (SnO2)). Cassiterite forms a crystal structure which helps prevent light from traveling through the glaze—creating an opacifying effect. In order to produce pink (rather than a deep red), we started scaling back the amount of chromium oxide introduced to the 5% SnO2 glaze, as that was when a clear, unmuddied red was first observed. If there is a lower concentration of chromium oxide to occupy the tin crystal lattice, and the same overall opacity, a lower saturation and more pastel red should be found. After eighteen chromium down-ramps, we found that while most red chromium glazes use around 0.2% chromium oxide, even 0.005% chromium oxide was enough to produce a soft pink, while anything at or above 0.025% seems to transition back toward the deeper raspberry red colors (2).

While these chromium amounts yield the desired shades of pink, they also produce speckles—possibly due to concentrated color centers. These color centers likely arise from defects in the structure of the tin-chromium lattice. While the speckling may be an effect that is desirable to some, it can be reduced by using a ball mill to evenly distribute the chromium oxide.1

With pinks set, it was pondered if purples could also be developed the same way. Traditionally, purples (similarly to pinks) are hard. The most common purple is neodymium oxide, making a dichroic lavender. It has about the same cost as erbium: $120/pound. And the pigment loading for neodymium is about the same, ringing in at 8% or so. That’s more than $200 for a bucket in just pigment alone.

Cobalt is a relatively strong pigment (but not so sensitive as chromium in tin, as shown earlier), so it was added in 0.05% increments and then doubled in the last row at 0.40%. This made for quite a colorful set of glazes that, to our knowledge, hasn’t been developed or shared to this date (3).

Raspberry Base Recipe

This is the base recipe for tin and chrome glazes to produce pinks and purples. Ferro frit 3134 provides a high calcium content that is essential in achieving the desired pink color.2 Calcium (in Ferro frit 3134) helps achieve opacity in the glaze at higher temperatures.3 It should also be noted that zinc should be avoided in this glaze recipe as it results in varying shades of brown. This could be because zinc could compete with chromium for open sites in the cassiterite crystal matrix (which chromium otherwise occupies and results in vibrant pinks and raspberries).

varying shades of brown. This could be because zinc could compete with chromium for open sites in the cassiterite crystal matrix (which chromium otherwise occupies and results in vibrant pinks and raspberries).

To obtain Julia’s Pink, as seen in the first mug for this article, add 0.010% Cr2O3 to the Raspberry Base Recipe. Be sure to pay attention to decimal places. It will be a very small amount of chromium!

While the exact mechanism for chromium-tin pink and raspberry glazes is not currently fully agreed upon, several different phenomena are taking place, including nanoparticle formation, chromium substitution in cassiterite matrix, and likely competition between Cr and Sn for that matrix position. It is interesting that nanomaterial quantities of chromium oxide are required for vibrant pinks and reds—much akin to metal loading content for nanoparticle gold and silver glazes as well.

Hopefully, this grid of pinks to purples helps those in need and inspires others to look at commonly used recipes and ask themselves how they work—and then start changing additives in the recipes. This range of pinks and purples has been sitting under potters’ noses for a decade now, just waiting for someone to ask how it works.

the authors Julia Krichev is a swimmer at the University of Richmond. She is currently studying biochemistry and visual arts at the University of Richmond.

Craig Caudill is currently pursuing a master’s of public health in epidemiology at the University of Michigan. He is a recent graduate from the University of Richmond, earning a BA with honors in leadership studies.

Ryan Coppage is currently chemistry teaching faculty at the University of Richmond. He fiddles with various glaze projects and makes a reasonable number of pots. To see more, visit www.ryancoppage.com.

1 Technofile: Demystifying Chrome Oxide for Fantastic Ceramic Glaze Color. https://ceramicartsnetwork.org/daily/article/Technofile-Demystifying-Chrome-Oxide-for-Fantastic-Ceramic-Glaze-Color.

2 Ibid.

3 Opacifiers. https://ceramicartsnetwork.org/ceramic-recipes/recipe/Opacifiers.

Unfamiliar with any terms in this article? Browse our glossary of pottery terms!

Related Content

Ceramic Artists

Functional Pottery

Ceramic Sculpture

Glaze Chemistry

High-Fire Glaze Recipes

Mid-Range Glaze Recipes

Low-Fire Glaze Recipes

Ceramic Colorants

Ceramic Glazes and Underglazes

Ceramic Raw Materials

Pottery Clay

Ceramic Decorating Tools

Ceramic Kilns

Making Clay Tools

Wheel Throwing Tools

Electric Kiln Firing

Gas Kiln Firing

Raku Firing

Salt Firing and Soda Firing

Wood Kiln Firing

Ceramic Decorating Techniques

Ceramic Glazing Techniques

Handbuilding Techniques

Making Ceramic Molds

Making Ceramic Tile

Wheel Throwing Techniques